400-0099-575

EN

Operating principle

With its simple operation,the JP series reel-type sprinkler adopts a water turbine-type water power drive system known for its durability.The unique design of the nozzle impact enables smooth transmission into the 4-speed gearbox even at very low flow rates,ensuring high recovery speed. After the speed reduction, a strong torque force will be generated through the gear or chain transmission to drive the winch rotation facilitating the automatic recovery of the PE pipe. Meanwhile, the high-pressure water flow out of the water turbine is directly channeled to the spray nozzle through the PE pipe. The spray nozzle evenly disperses the high-pressure water flow over the crops, transforming it into tiny water droplets that land uniformly, This continuous and uniform spraying operation with the movement of the PE pipe.

A built-in flow control valve is installed at the water turbine inlet. The water flow into the impact blade of the water turbine can be adjusted by changing the opening degree of the valve thereby altering the rotational speed of the water turbine shaft. This adjustment in the PE pipe's movement speed allows for achieving different precipitation depths. The rotor shaft of the adjusting valve changes at different angles between the PE pipes of the reel layers through the pressure bar pressed on the PE pipes and drives the automatic flow control of the flow control valve through the interlayer differential flow control linkage, The sprinkler lacks a speed coding display, ensuring that during operation, the recycling speed of the PE pipe can be maintained at nearly a constant speed when winding, thus achieving the goal of uniform spraying through automatic flow regulation.

The sprinkler has significant advantages over water turbine-driven models, including a compact structure, low head pressure, uniform irrigation, high overall efficiency, precise control and strong adaptability. It represents a new category of efficient agricultural irrigation and spraying equipment.

The sprinkler utilizes a motor-driven reel to facilitate the recycling of PE pipes, with a PLC touch screen program controlling the intensity and operation time of irrigation. It can also be remotely controlled and monitored through a customized mobile phone APP. The system can be configured with either a single spray head car or a multi-spray-head truss-type car ensuring low head pressure, high spraying uniformity, minimal impact on crops, simple and convenient operation, high efficiency and energy-saving. Shuoyuan's new generation of high-quality water-saving irrigation and spraying equipment is the result of a professional management team, senior design experts, modern processing equipment and a constantly improving enterprise culture.

Production introduction

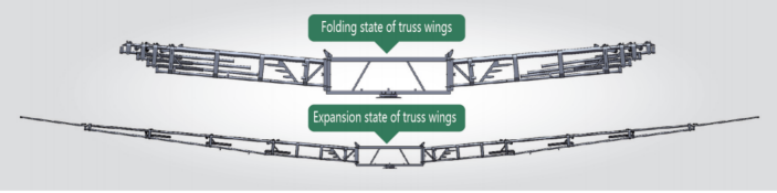

Rotary pull-folding truss can be combined with reel sprinkler as an integration machine. This new truss offers easy movement ,low cost, high irrigation precision and excellent performance. It is an ideal supporting spray terminal equipment for reel sprinkler,and represents an optimal solution for achieving low pressure and water saving sprinkling irrigation.

1. The retractable folding truss featuring a segmented retractable structure can be folded in bilateral symmetry.It can also be integrated with a reel sprinkler, making it convenient for area transfer.

2. The retractable folding truss is equipped with an automatic stop structure, ensuring reliable extension and easy operation. It can be extended or folded by a single person in 5 minutes.

3. The retractable folding truss has a wing width of 30 meters after expansion, and the one-way spraying width can extend up to 38 meters.

4. The retractable folding truss has a rotary function that effectively allows it to navigate around obstacles in the field, such as telegraph pole and tree, etc.

5. The retractable folding truss offers advantages such as scientific and reasonable design, low working pressure, energy saving ,small sprayed droplets, uniform distribution of water, minimal impact on crops and soil,low susceptibility to wind, and high efficiency in sprinkling irrigation.(patent number: 201821728456.X)

Introduction to the product

Water and fertilizer integration technology is an innovative agricultural technology that integrates irrigation and fertilization. This comprehensive agricultural irrigation method utilizes sprinkler irrigation to simultaneously apply soluble solid or liquid fertilizers. The fertilizers are mixed with irrigation water based on the soil’s nutrient content and the specific fertilization requirements of various crop types. By achieving a homogeneous blend of water and fertilizer, this technique ensures the uniform, timely,and precise delivery of water and nutrients. The design takes into consideration the specific water and fertilizer requirements at various stages of crop growth, ensuring the precise delivery of water and nutrients in suitable proportions directly to the crops. Water and fertilizer integration encompasses multiple aspects of agricultural irrigation, crop cultivation, and soil management. Anhui shuoyuan Agriculture Water Saving Technology Co. Ltd. has conducted extensive research and development on a new type of water and fertilizer integration sprinkler fertigation machine, which has secured numerous national invention patents.

Structure and working principle of irigation fertilizer applicator

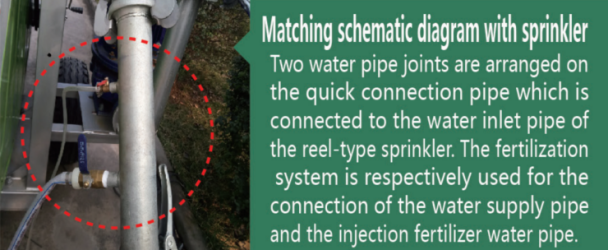

The fertilization system operates by utilizing solar photovoltaic power or battery power. It allows adjustable and quantitative fertilizer application. The system consists of a fertilizing tank, an automatic or manual water control system, a fertilizer injection pump, a fertilization device, a mixer, pipelines, valves, and other components.

Main technical parameters of integrated

Volume of fertilizer tank:300L/500L/800L

Stirring motor:24V/48V,60W300R/MN

Fertilizer pump:24V80W/48V80W

Maximum pressure 1.0MPA

Flow rate:3L/min

Storage cell:24V/48V 20AH-40AH

Main technical parameters of water fertilizer machine

Volume of fertilizer tank L 300L/500L/800L

Power supply voltage V AC380V(AV220,DC24V,available)

Total power W 240~300(Maximum)

Rated flow L/min 5.5~12.5

Fertilizer injection rate L/min 0.3-7(5.5kg entry pressure)

Suction M 1.5